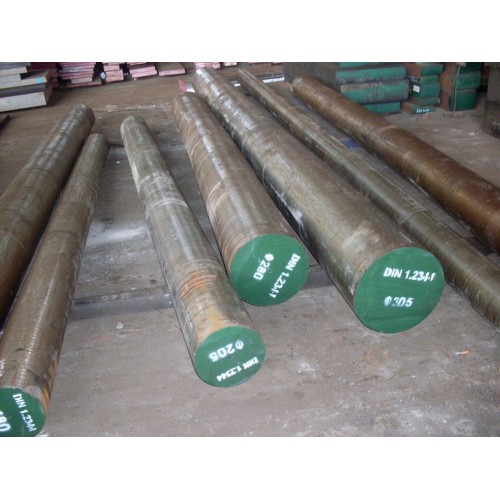

2311 Plastic Mould Steel | P20 steel | NAK55 | P20+Ni | 3Cr2Mo

Price:

R.F.Q.

Share Product:

Detail

1.2311 Plastic Mould Steel (or known as 40CrMnMo7)

1.2311 is a pre-hardened high tensile tool steel which offers ready machineability in the hardened and tempered condition, therefore does not always require further heat treatment. This eliminates the risks, cost, and waiting time of heat treatment and avoids the associated possibility of distortion or even cracking. Subsequent 1.2311 component modifications can easily be carried out.

----------

Technical Data :

Hardening : Heat uniformly to 840/870°C until heated through. Quench in oil.

Nitriding : Moulds machined from pre-hardened 1.2311 may be nitrided to give a hard surface which is very resistant to wear and erosion. A nitrided surface also increases the corrosion resistance. The surface hardness after nitriding at a temperature of 525°C in ammonia gas will be approximately 650HV.

Tufftriding : Tufftriding at 570°C will give a surface hardness of approximately 700HV. After 2 hours treatment, the hard layer will be approximate 0.01mm

Flame & Induction Hardening : 1.2311 may be flame or induction hardened to a hardness of 50 to 55 HRc. Cooling in air is a preferable option. Smaller pieces may however require forced cooling. Hardening should be immediately followed by tempering.

Hard Chromium Plating: After hard chromium plating the steel should be tempered for approximately 4 hours at 180°C, in order to avoid hydrogen embrittlement.

Case Hardening: In order to maintain maximum surface hardness 1.2311 may be case hardened. Before case hardening is carried out the steel should be annealed. To carburise, pack with carburising powder into a cast iron or heat-resisting steel box and see that the articles are separated from the sides by at least two inches of carburising powder. Lute the lid with fireclay. Heat to the carburising temperature of 880°C and soak for sufficient time to give the required depth of case. Cool to 800/820°C and quench in oil. Tempering will then be necessary. Reheat to 200/300°C and allow to cool in the air to give a final surface hardness of Rockwell C55/59

Welding: Firstly heat to approximately 400 to 500°C. Weld .12311 at approximately 400 to 500°C and stress relieve. Use Chromium-Nickel-Molybdenum alloyed basic electrodes for welding of structural steels. Welding may also be carried out using an austenitic stainless steel electrode. In this case the stipulated increased working temperature may be modified, but the weld metal has a lower strength than the parent material.

Specification

| Keyword | |

| Origin | CN |

Catalogue Download