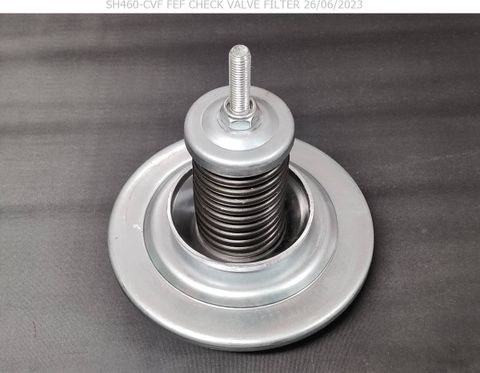

CHECK VALVE

Last Update

Price:

R.F.Q.

Share Product:

Detail

A check valve, also known as a one-way valve, is crucial in hydraulic systems, including those used in excavators, to allow fluid flow in one direction while preventing backflow. If a check valve fails to function properly, it can lead to several significant issues affecting the performance, safety, and reliability of the hydraulic system. Here are the common problems associated with a non-functional check valve:

1. Hydraulic System Issues

Backflow and Contamination:

- Reverse Flow: A malfunctioning check valve can allow hydraulic fluid to flow backward, leading to contamination and mixing of fluids, which can reduce the efficiency of the system.

- Component Damage: Backflow can cause damage to sensitive components that are not designed to handle reverse flow, leading to increased wear and potential failure.

Pressure Loss:

- Inefficiency: A faulty check valve can result in a loss of hydraulic pressure, reducing the system's overall efficiency and performance.

- Reduced Force: Hydraulic actuators, such as cylinders and motors, may not receive sufficient pressure to operate correctly, leading to decreased lifting and digging power.

2. Operational Problems

Erratic Movements:

- Unpredictable Operation: A malfunctioning check valve can cause erratic or unpredictable movements of the excavator's boom, arm, or bucket, making precise control difficult and potentially hazardous.

- Safety Risks: Uncontrolled movements can pose safety risks to the operator and nearby workers, increasing the likelihood of accidents.

Hydraulic Lock:

- System Stalling: In some cases, a failed check valve can cause a hydraulic lock, where fluid becomes trapped and prevents the system from operating. This can lead to the machine stalling or failing to perform certain functions.

3. Increased Wear and Tear

- Component Strain:

- Excessive Wear: Continuous operation with a malfunctioning check valve can place additional strain on other components, leading to increased wear and a higher likelihood of premature failure.

- Frequent Maintenance: The system may require more frequent maintenance and component replacements due to the increased wear and tear caused by improper fluid flow.

4. System Inefficiency

- Reduced Performance:

- Lower Productivity: A non-functional check valve can reduce the excavator's overall productivity by causing slow or inefficient hydraulic operations, leading to longer cycle times for tasks such as digging, lifting, and loading.

- Energy Loss: Inefficiencies in the hydraulic system can lead to increased energy consumption, reducing the machine's fuel efficiency and increasing operational costs.

5. Safety Concerns

- Unreliable Braking:

- Brake Systems: In excavators equipped with hydraulic braking systems, a faulty check valve can compromise the reliability of the brakes, posing significant safety risks during operation, especially on inclines or uneven terrain.

- Emergency Situations: Inability to rely on hydraulic systems for emergency stops can lead to dangerous situations and potential accidents.

6. Increased Maintenance Costs

- Frequent Repairs:

- Diagnostic Time: Identifying and diagnosing issues caused by a faulty check valve can be time-consuming, leading to increased labor costs.

- Component Replacement: Repeated failure of check valves can necessitate frequent replacement of the valves and other affected components, increasing maintenance expenses.

Summary

A non-functional check valve can lead to hydraulic system issues, operational problems, increased wear and tear, system inefficiency, safety concerns, and increased maintenance costs. Ensuring that check valves are regularly inspected, maintained, and promptly replaced if faulty is crucial for maintaining the performance, efficiency, and safety of the hydraulic system in excavators. Regular maintenance and timely repair of check valves can help prevent these issues and ensure smooth and reliable operation.

Catalogue Download