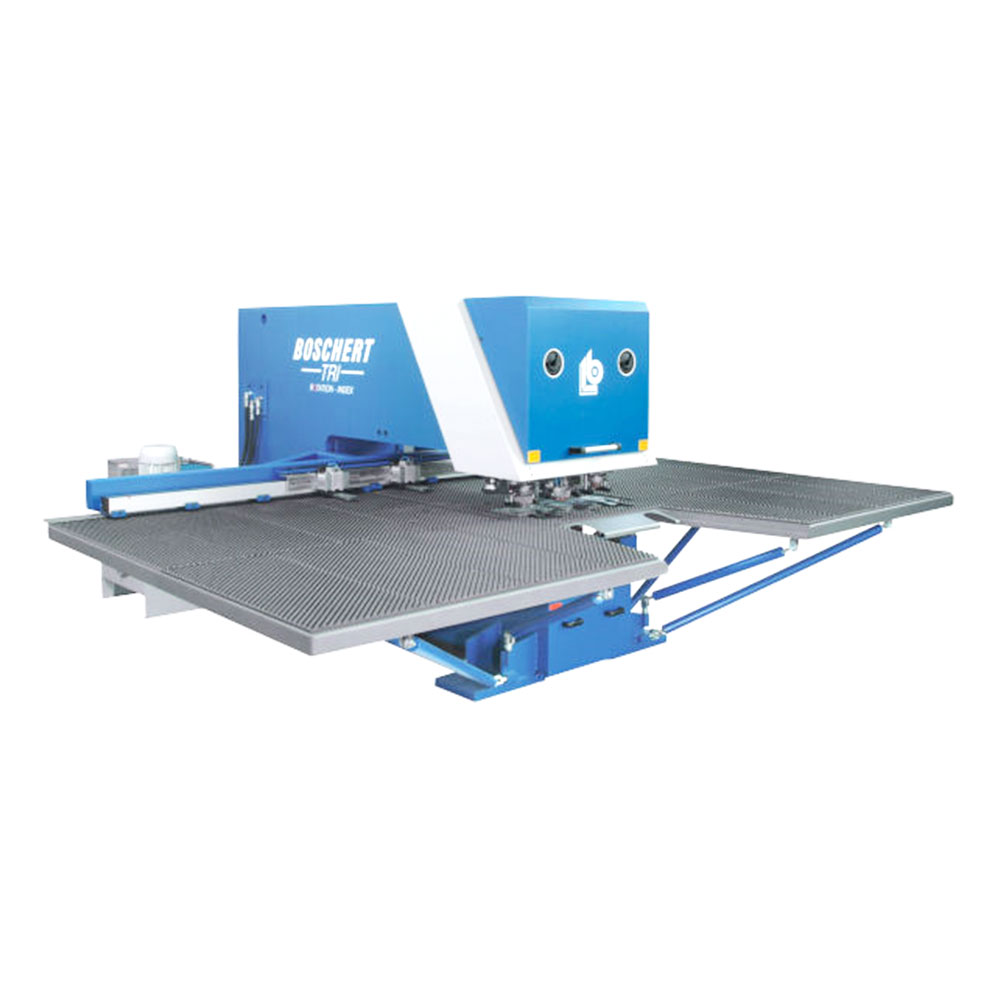

Boschert Punching Machines TWIN/TRI

Price:

R.F.Q.

The TWIN/TRI series machines are equipped, respectively with two or three independent punch heads. Either series can be equipped with Revotool, Boschert‘s multi-tool solution. Up to 16 tools in the TWIN series and up to 24 tools in the TRI series allow the working of complex parts without tool change. A distinct advantage of all Boschert CNC punching machines is the user-friendly software. The heavy duty, open C-frame design allows turning of over sized sheets. The powerful software suggests options for automatic re-positioning and turning/flipping of large parts.

Share Product:

Detail

Rotation Index

One of the heads in either series machine can be equipped with full 360 step-less rotation of all tools up to 105 mm in diameter. Designed especially for rotation machines, a 7-position Revotool includes a 5mm x 30mm parting tool thus allowing contouring, shaker parts, etc. In addition to the slitting tool, 6 positions with a maximum diameter of 16 mm are accommodated.

More components of the TWIN / TRI series

- An L-sheet is provided with all machines for working very small pieces and pre-bent parts. (Standard)

- The automatic tool lubrication serves to increase tool life when nibbling stainless steel (VA) and decreases edge burrs in aluminium

- Re-positioning up to 10 meters and clamp movement without contacting the sheet. 2 robust clamps for sheets up to 200 kg (expandable to 4 clamps). Standard capacity up to 7 mm or 12,7 mm when required. (Standard)

- Sandblasted, corrosion resistant surface as standard. Balls in the table for heavier sheets and easy handling, brushes in the table for thin or scratch sensitive sheets are also available.

- Vacuum slug removal

- CNC/CAD software to import DXF-files into machine language, calculated punch time, graphic simulation

- Nibbling up to 800 strokes / min with integrated oil cooling

- Programmable re-positioning of the clamps for faster set up of the machine.

- Tapping and drilling attachment for threads M3 up to M12 and smaller drilled holes in thicker sheets.

- Marking apparatus for marking parts in 10 different fonts.

- Punching power 400 kN

Specification