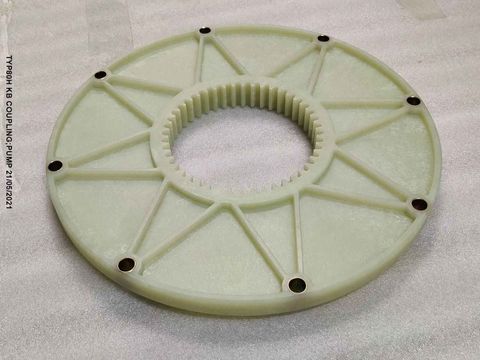

Coupling

価格:

R.F.Q

Share Product:

詳細

If a coupling, such as a shaft coupling or a flexible coupling, develops a crack, it can lead to several issues that affect the operation, performance, and safety of machinery or equipment. Couplings are used to connect two shafts together for transmitting power or torque. Here are some potential problems that can arise from a cracked coupling:

Reduced Power Transmission: One of the primary functions of a coupling is to transmit power or torque from one shaft to another. If a coupling develops a crack, it can compromise the integrity of the coupling, leading to reduced power transmission capability. This can result in decreased performance or efficiency of the machinery or equipment, as the full power or torque may not be effectively transferred between shafts.

Vibration and Misalignment: A cracked coupling can cause vibration and misalignment issues in the connected shafts. The crack may introduce a point of weakness or imbalance in the coupling, causing it to wobble or vibrate during operation. Vibrations can lead to increased wear and tear on the shafts, bearings, and other components, potentially causing further damage or malfunction.

Increased Noise: Cracks in a coupling can also contribute to increased noise levels during operation. As the crack propagates or the coupling becomes misaligned, it may produce rattling, knocking, or grinding noises as it rotates. Excessive noise can indicate underlying issues with the coupling and should be investigated to prevent further damage.

Shaft Failure: In severe cases, a cracked coupling can lead to shaft failure. The crack may continue to propagate under the stress of operation, eventually causing the coupling to fail completely. This can result in the disconnection of the shafts, loss of power transmission, and potential damage to surrounding machinery or equipment.

Safety Hazards: A cracked coupling poses safety hazards to operators and nearby personnel. If the coupling fails unexpectedly during operation, it can result in sudden equipment malfunction or shutdown, potentially causing accidents or injuries. Additionally, loose or detached coupling components may become projectiles, posing a risk to anyone in the vicinity.

Downtime and Maintenance Costs: Addressing a cracked coupling typically requires equipment downtime for inspection, repair, or replacement. Downtime can disrupt production schedules and result in lost productivity and revenue. Additionally, repair or replacement of a cracked coupling incurs maintenance costs, including parts, labor, and potential expenses associated with troubleshooting and diagnosis.

In summary, a cracked coupling can lead to reduced power transmission, vibration and misalignment issues, increased noise levels, shaft failure, safety hazards, downtime, and maintenance costs. Prompt detection and repair or replacement of a cracked coupling are essential to ensure the reliable and safe operation of machinery or equipment. Regular inspection and maintenance of couplings can help prevent issues and prolong their service life.

仕様書

| キーワード | |

| ブランド | |

| 起源 | MY |