Sintering Materials

価格:

R.F.Q

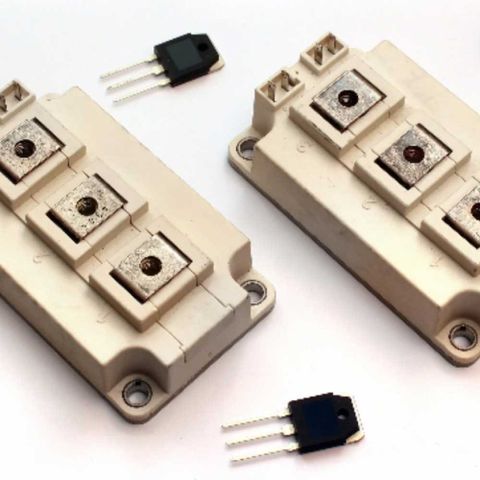

Sintering materials, which include thermoset hybrid-sintering epoxy based adhesives and silver-based pastes, are used for high-power die attach applications. These materials are valued for their combination of high temperature resistance and best-in-class thermal and electrical conductivity. They are well-suited for applications such as power semiconductors, LEDs, automotive EV power modules, and RF devices. Despite their high filler loading, these materials have a relatively low viscosity, which makes them well-suited for easy application like dispensing and stamping.

Share Product:

詳細

Key Properties

Formulation: Silver and copper sintering pastes, and hybrid-sintering epoxy based adhesives.

Applying Methods: Dispensing, stamping, stencil printing

Sintering Methods:

- Pressure-assisted: Drying at 200°C for 10 mins and sintering at 250°C for 5 mins

- Pressure-less: 200°C for 1 hour

- Hybrid-sintering epoxy based adhesives: 120°C for 15 mins and ramp up to 200°C in 15 mins

Volume Resistivity:

- Sintering Pastes: As low as 4 x 10-6 Ohm.cm

- Hybrid-sintering epoxy based adhesives: As low as 3.8 x 10-6 Ohm.cm

Thermal Conductivity:

- Sintering Pastes: >200 W/m.K

- Hybrid-sintering epoxy based adhesives: >60 W/m.K

Work Life: Up to 24 hours

Application-Specific Options:

- Variety of viscosity for different application methods.

- Choice of silver or copper-based materials.

- Versions with improved electrical conductivity.

- Options specifically designed for high-speed, fine dot dispensing.