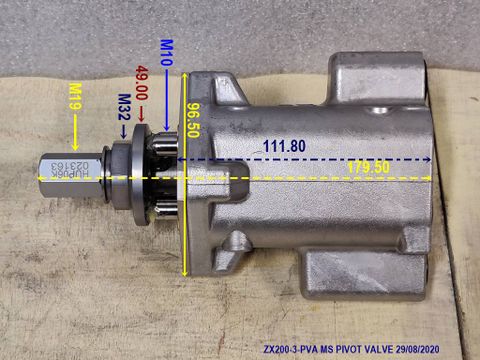

PIVOT JOYSTICK Excavator Spare Part HITACHI KOMATSU VOLVO

கடைசியாக புதுப்பிக்கப்பட்டது

விலை:

R.F.Q

Share Product:

விவரம்

Free Catalogue Website: www.heavypartshub.com

A pivot joystick in an excavator is crucial for controlling various movements and functions of the machine, such as the boom, arm, bucket, and swing operations. If the pivot joystick fails to function properly, it can lead to several significant issues affecting the performance, safety, and operational efficiency of the excavator. Here are the common problems associated with a non-functional pivot joystick:

1. Loss of Control

- Inability to Operate the Excavator:

- Movement Restrictions: A non-functional joystick can prevent the operator from moving the boom, arm, bucket, or rotating the cab, severely limiting the machine's capabilities.

- Operational Downtime: The excavator may be rendered inoperable, leading to significant downtime and delays in project completion.

2. Safety Concerns

- Accidents and Injuries:

- Unpredictable Movements: If the joystick intermittently fails or causes erratic movements, it can lead to accidents, posing a risk to the operator and nearby workers.

- Emergency Situations: Inability to control the excavator in emergency situations can prevent timely responses, increasing the risk of injury or equipment damage.

3. Operational Inefficiency

- Reduced Productivity:

- Slow Operations: Difficulty in controlling the excavator's functions can slow down operations, reducing overall productivity and efficiency.

- Manual Intervention: Operators may need to resort to manual intervention or alternative controls, which can be time-consuming and less efficient.

4. Increased Wear and Tear

- Component Stress:

- Unintended Stresses: Improper or erratic control can place unintended stresses on hydraulic components and mechanical parts, leading to increased wear and tear.

- Frequent Maintenance: Increased wear may necessitate more frequent maintenance and repairs, leading to higher operational costs.

5. Troubleshooting and Maintenance Challenges

- Diagnosis Difficulties:

- Complex Repairs: Diagnosing issues with the joystick and its associated electronic or hydraulic control systems can be complex and time-consuming.

- Intermittent Failures: If the joystick fails intermittently, it can be challenging to pinpoint the exact cause, leading to extended troubleshooting and repair times.

6. Hydraulic System Impact

- Pressure and Flow Issues:

- Inconsistent Pressure: A malfunctioning joystick can cause inconsistent hydraulic pressure and flow, affecting the performance of the excavator's functions.

- System Strain: Erratic control can strain the hydraulic system, potentially leading to leaks, pressure losses, and component failures.

7. Electrical and Electronic Problems

- Signal Interruption:

- Communication Failures: Modern excavators rely on electronic signals from the joystick to control hydraulic functions. A non-functional joystick can interrupt these signals, leading to unresponsive controls.

- Wiring Issues: Electrical problems such as damaged wiring or connectors can cause joystick malfunctions, requiring detailed inspections and repairs.

Summary

A non-functional pivot joystick in an excavator can lead to loss of control, safety concerns, operational inefficiency, increased wear and tear, troubleshooting and maintenance challenges, hydraulic system impacts, and electrical and electronic problems. Ensuring that the joystick is regularly inspected, maintained, and promptly repaired or replaced if faulty is crucial for maintaining the performance, safety, and efficiency of the excavator. Regular maintenance and timely repair of the pivot joystick can help prevent these issues and ensure smooth and reliable operation.

பட்டியல் Download